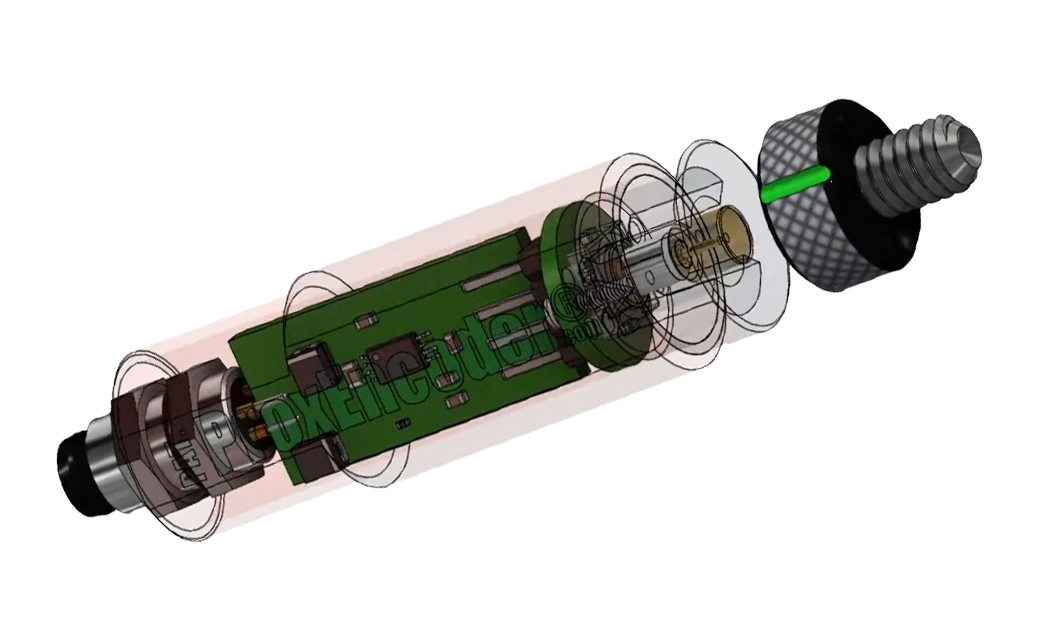

GHOST VIEW SHOWING MOVING

NON-CONTACT ENCODER MAGNET

WHAT MAKES

ProxEncoder ® DIFFERENT?

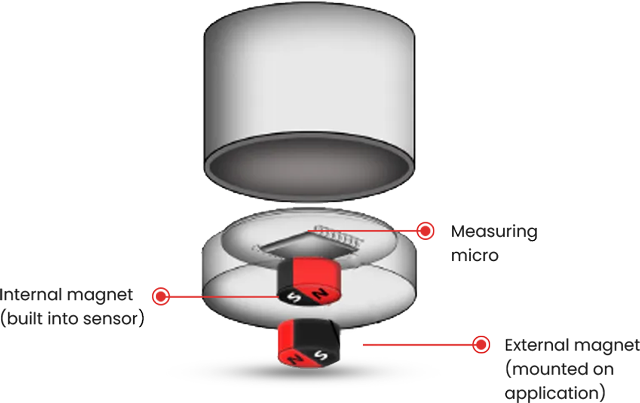

Flux Coupled Sensor Magnet

All other NON-CONTACT encoders or angle position sensors rely on the application magnet (the magnet mounted to the moving part) be in direct contact with the hall array inside the sensor. The GAP distance – the distance between the magnet and the sensor – is generally less the 2 mm, and more important – the axial alignment be better then .1 mm.

So the machine bearing become the encoder bearings. Any wear in the bearings makes the encoder data less reliable. Just not a good design solution.

JORAL’s Patented solution – is to install the magnet used for position sensing INSIDE the encoder on a low friction ruby bearing.

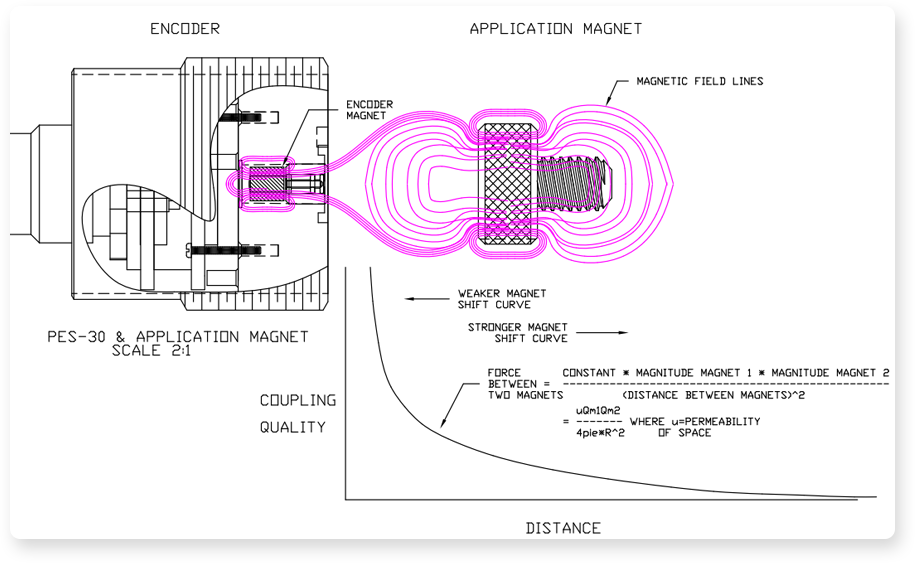

FLUX LINES ADD FLEXIBILITY

JORAL’s Patented solution – The outside magnets flux lines – couple with the inside sensed magnet – like a kid playing with two magnets under a table. Now the critical alignment is maintained by the inside magnet – which is mounted on ruby bearings, this allows the outside magnet has a greater degree of freedom in positioning.

The flux lines in photo are represented in purple.

PATENTS

US20090072816A1

US20120153940A1

PROXENCODER TRADEMARK

ENGINERRING OR APPLICATION QUESTIONS?

Drop us a line and an engineer will email your answer.

Email and an Engineer will get back to you,

Please describe the issue or the application so we may be of assistance.